University of

Oxford

-

Programme

MSc by Research, Materials Science

-

Topic

Graphene-Reinforced PAN Nanofibres for High-Performance Carbon Fibre Applications

-

Year

2021-2024

The global shift toward a low-carbon economy increases the demand for advanced materials like carbon fibres, especially in automotive and renewable energy sectors. This MSc by Research was carried out as a dedicated research position within Oxford’s Materials Department and focused on enhancing the performance of carbon fibres by integrating in situ synthesised graphene into PAN precursor fibres.

The work combines materials chemistry, nanomanufacturing and advanced characterisation to deliver a scalable method for producing high-performance nanofibres — with direct relevance for next-generation composite materials and industrial manufacturing.

Research Summary

Polyacrylonitrile (PAN) is the leading precursor in carbon fibre manufacturing because of its high carbon yield and mechanical strength. The performance of carbon fibres is directly determined by the properties of the PAN precursor fibres. However, current production methods do not fully exploit the theoretical mechanical potential of PAN.

Enhancing the mechanical performance of PAN fibres by incorporating graphene is promising, but commercial graphene typically exhibits low quality, with high defect densities and multiple layers (>10 layers), with dispersion being an additional challenge.

In Situ Graphene Synthesis in PAN Solutions

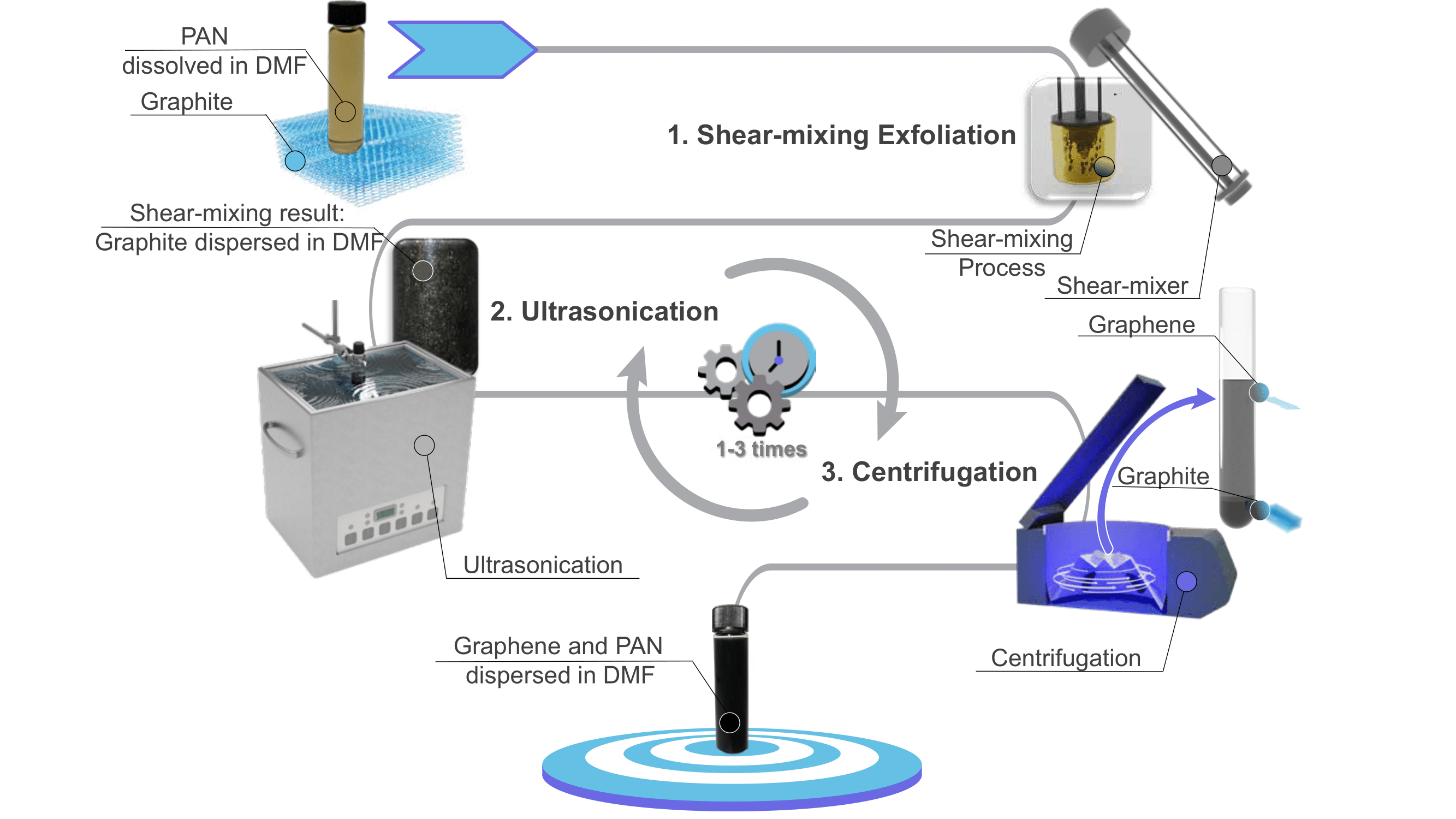

This study addresses these limitations by introducing a novel approach: incorporating in situ synthesised graphene into PAN precursor solutions, achieving a uniform dispersion of 0.21 mg/ml graphene with an average of nine layers. The key steps of the novel synthesis process are summarised in the schematic below:

Electrospinning of Graphene-Reinforced PAN Fibres

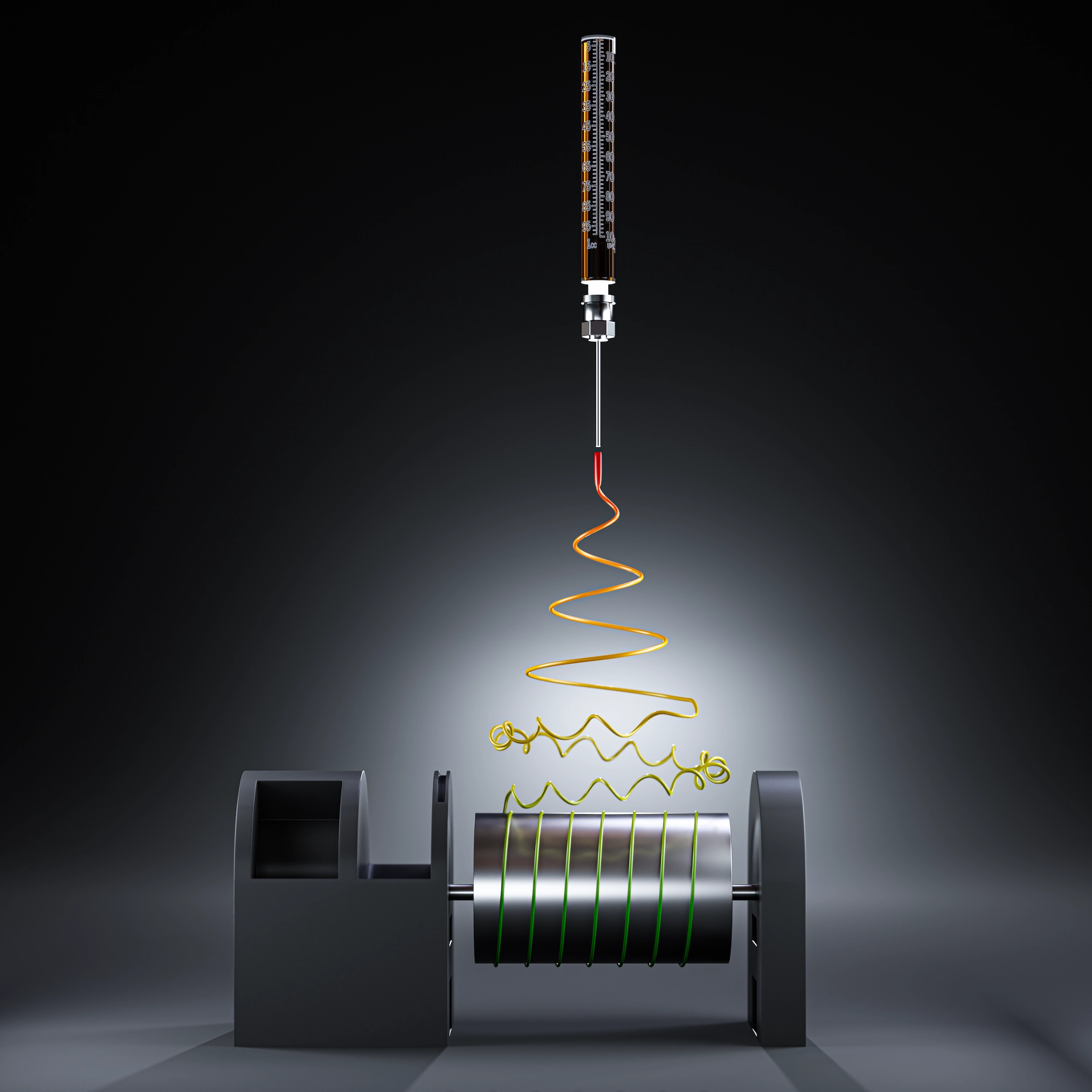

The precursor solution is then used to produce fibres via electrospinning on a drum collector, rotating at approximately 8000 rpm, corresponding to a linear velocity of ∼67 m/s. The schematic on the left illustrates the electrospinning process, while the right shows a high-speed drum collector I independently developed — teaching myself mechanical design and Fusion 360 to deliver a custom-built 8000 RPM prototype that outperformed commercial alternatives:

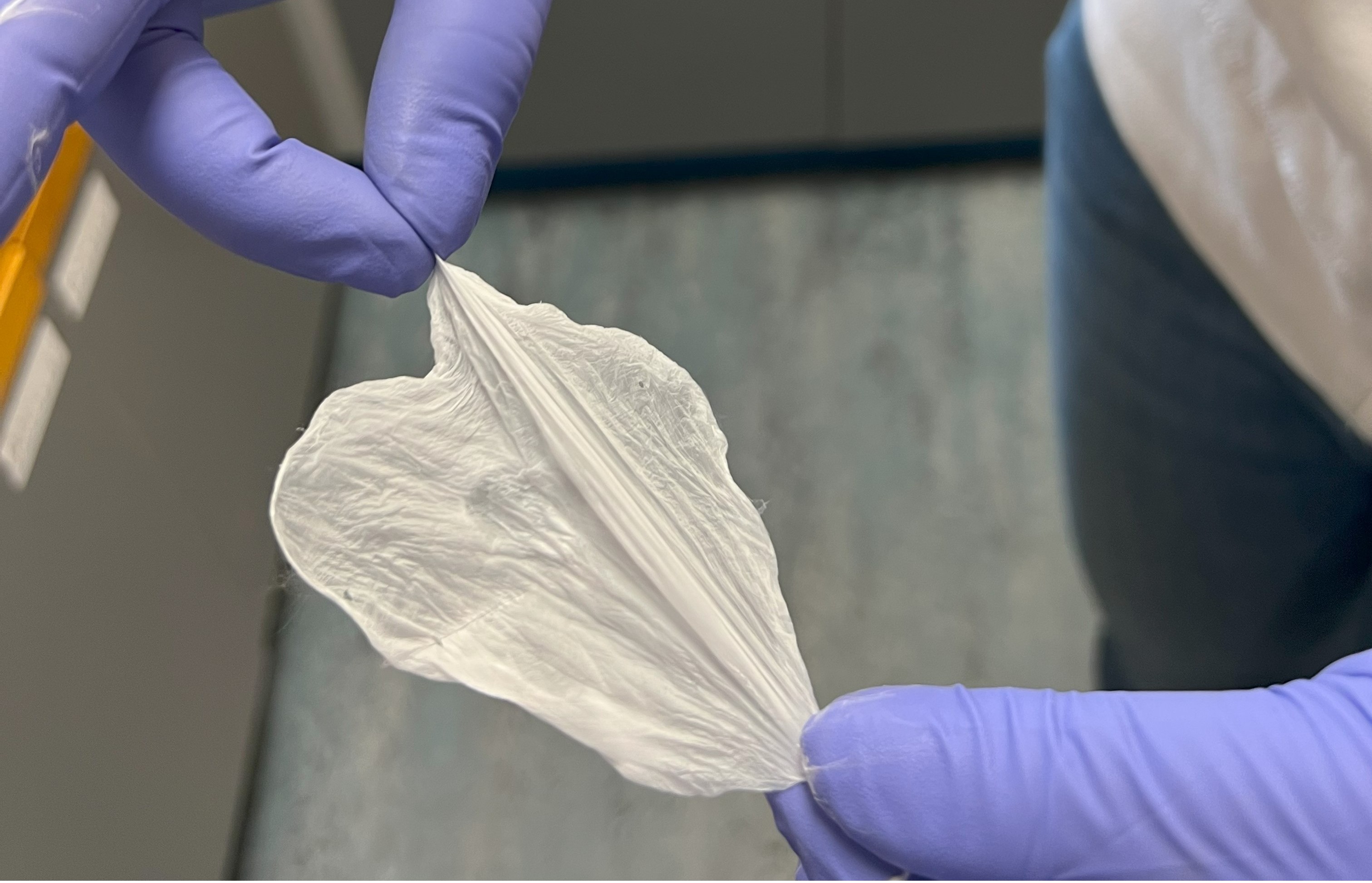

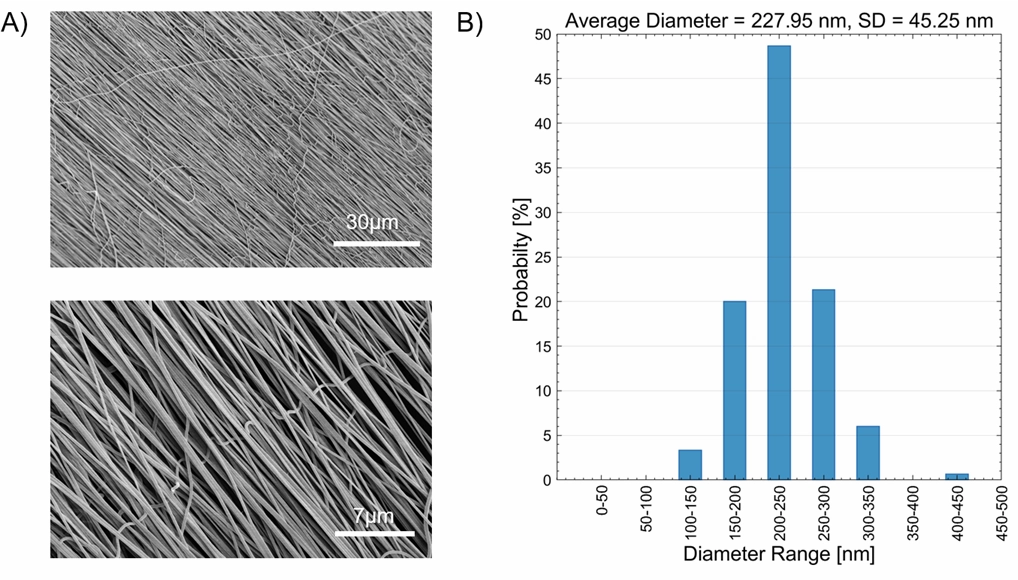

This process produces uniform, graphene-reinforced fibres with an average diameter of 228±45 nm, demonstrating a threefold improvement in stretchability over non-reinforced fibres. The left image shows the electrospun fibre mat, while the right image presents high-resolution scanning electron microscope (SEM) images and a diameter distribution plot, revealing the aligned structure and uniform thickness of the fibres:

Custom TGA Method for Graphene Detection in Composites

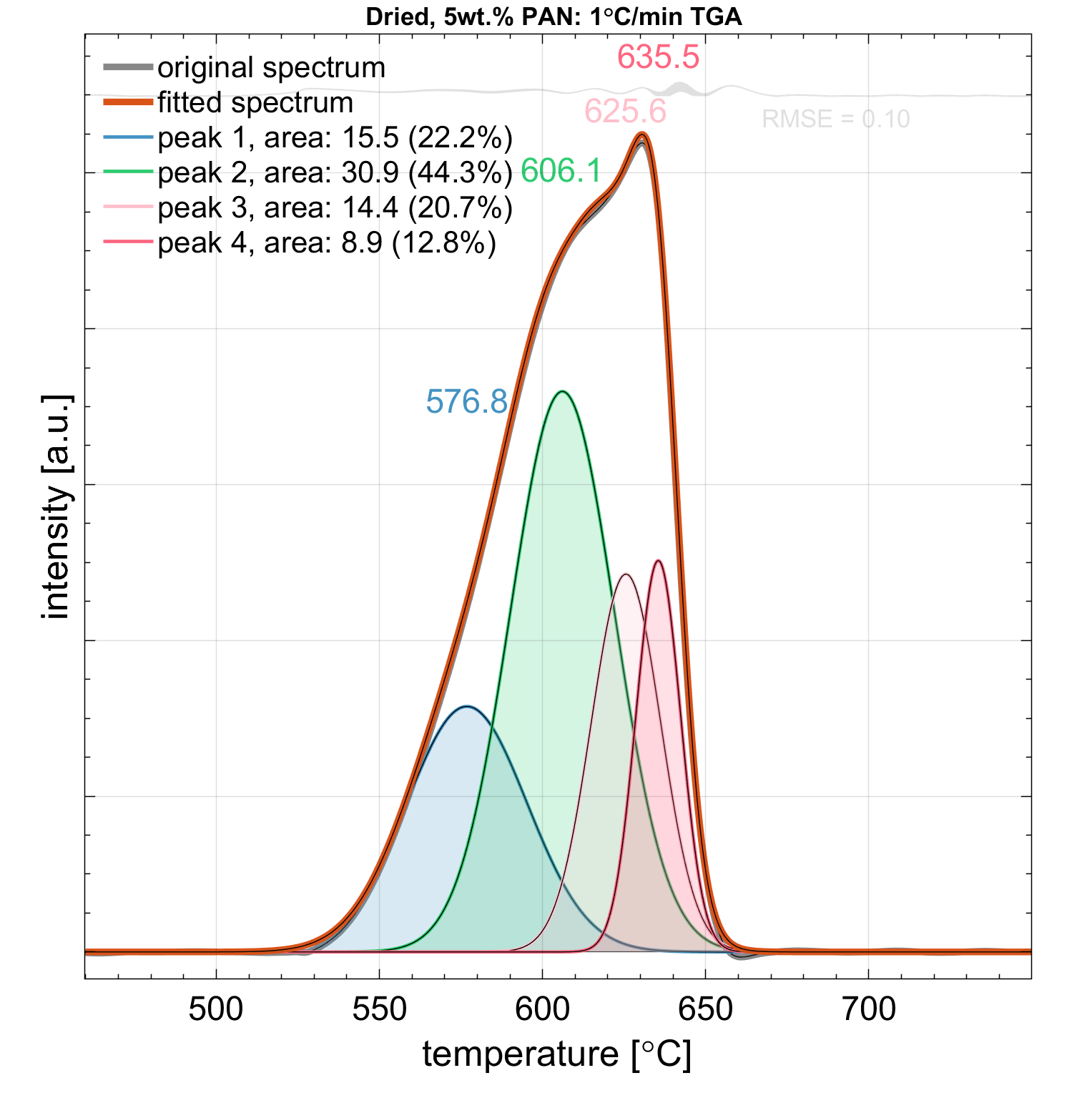

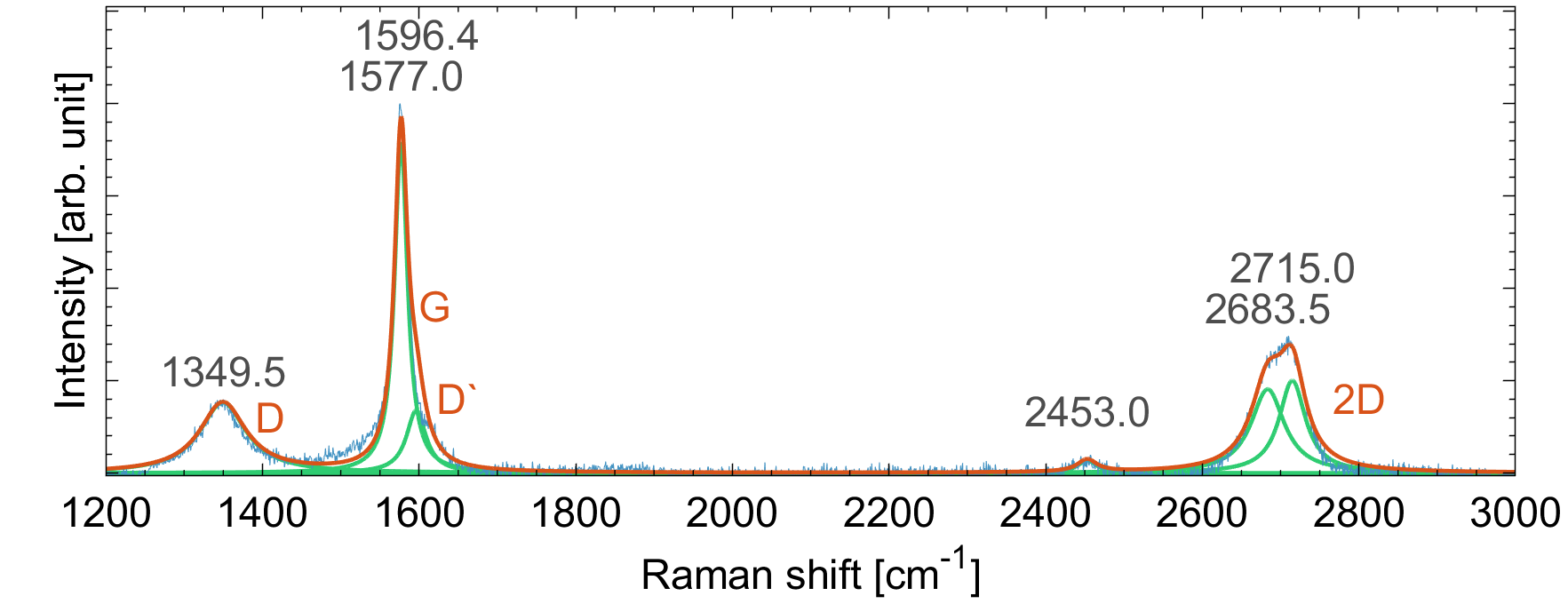

Furthermore, advanced thermogravimetric analysis (TGA) is developed as a rapid evaluation tool for graphene-polymer composites. The advanced TGA of the PAN-graphene composite confirms successful graphene integration and identifies a previously unobserved decomposition event at 412 °C, specific to shear-exfoliated graphene. The left image shows part of the custom TGA analysis workflow developed to detect graphene within the polymer matrix. To validate the method, complementary characterisation techniques such as Raman spectroscopy (right) were employed, confirming the material quality and graphene integration:

Why It Matters

In this project, I took full responsibility for designing, adapting, and validating experiments. Working in a fast-paced research group taught me to think critically, collaborate effectively, and extract clear conclusions from complex data. Our findings show the potential of graphene-enhanced PAN fibres as a foundation for next-generation carbon materials. Future work should focus on integrating electrical and mechanical optimisation strategies to further enhance fibre performance.

The research group at Oxford Materials. Grateful for the opportunity to work alongside so many bright minds.